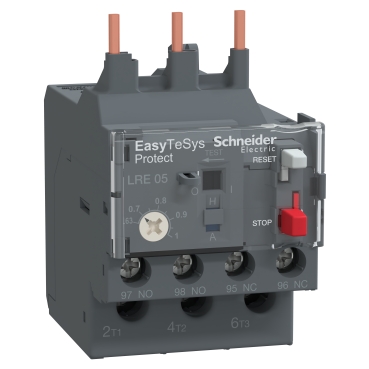

Schneider LRE05 | Thermal overload relay,EasyPact TVS,0.63…1A,class 10A

Schneider LRE05 description

The Schneider LRE05 is an overload relay designed to protect electrical motors from overheating and damage due to excessive current. It is an essential component in motor control systems, ensuring that motors operate within safe parameters. Overload relays like the LRE05 are crucial for preventing costly damage and downtime in various industrial applications.

Key Features of the LRE05

The Schneider LRE05 boasts several key features that make it a reliable choice for motor protection:

- Adjustable Trip Settings: Allows customization based on specific motor requirements.

- Thermal Overload Protection: Ensures motors are protected from overheating.

- Compact Design: Facilitates easy integration into existing systems.

- Manual and Automatic Reset Options: Provides flexibility in operation and recovery.

- Wide Range of Current Ratings: Suitable for various motor sizes and types.

Technical Specifications

Electrical Specifications

Understanding the electrical specifications of the Schneider LRE05 is vital for ensuring proper application and compatibility:

- Current Range: 0.1 to 32 A

- Voltage Rating: Up to 690 V AC

- Frequency: 50/60 Hz

- Breaking Capacity: High breaking capacity to handle fault conditions

Mechanical Specifications

The mechanical specifications determine how the LRE05 can be integrated into systems:

- Mounting Type: DIN rail or panel mounting

- Dimensions: Compact and space-saving design

- Weight: Lightweight for easy handling and installation

Environmental Specifications

Environmental conditions play a significant role in the performance of the LRE05:

- Operating Temperature: -20°C to +60°C

- Storage Temperature: -40°C to +80°C

- Humidity Resistance: Designed to operate in high humidity environments

- IP Rating: IP20, ensuring protection against solid objects

Applications of the Schneider LRE05

Industrial Uses

The Schneider LRE05 is widely used in various industrial settings, including:

- Manufacturing Plants: Protects motors in production lines from overload conditions.

- Pumping Stations: Ensures reliable operation of pumps by preventing motor damage.

- HVAC Systems: Maintains the efficiency of heating, ventilation, and air conditioning systems.

Commercial Applications

Beyond industrial uses, the LRE05 also finds applications in commercial environments:

- Building Automation: Integral in motor protection for automated building systems.

- Elevators and Escalators: Ensures safe and reliable operation of motors in vertical transportation.

Installation and Setup

Pre-installation Requirements

Before installing the Schneider LRE05, ensure that you have:

- Correct tools for mounting and wiring

- Appropriate personal protective equipment (PPE)

- A thorough understanding of the system requirements

Step-by-Step Installation Guide

- Turn Off Power: Ensure that the power supply to the motor control system is turned off.

- Mount the Relay: Secure the LRE05 onto the DIN rail or panel.

- Connect Wiring: Follow the wiring diagram provided in the manual to connect the relay to the motor circuit.

- Set Trip Values: Adjust the trip settings according to the motor’s specifications.

- Test the System: Turn on the power and perform a test to ensure the relay is functioning correctly.

Safety Precautions

- Always follow electrical safety guidelines.

- Ensure proper grounding of the relay.

- Regularly inspect the relay and associated wiring for signs of wear or damage.

Operation and Performance

How to Operate the LRE05

Operating the Schneider LRE05 is straightforward:

- Monitor: Regularly check the relay’s status indicators.

- Reset: Use the manual or automatic reset feature if the relay trips.

Performance Metrics

The performance of the LRE05 can be evaluated based on:

- Accuracy of Trip Settings: Ensures the relay trips at the specified current levels.

- Response Time: Quick response to overload conditions to protect the motor.

- Durability: Long operational life even under demanding conditions.

Maintenance and Troubleshooting

Routine Maintenance Tips

- Inspect Regularly: Check for dust accumulation and clean as necessary.

- Test Periodically: Perform routine tests to ensure the relay functions correctly.

- Update Firmware: If applicable, keep the relay’s firmware updated for optimal performance.

Common Issues and Solutions

- False Tripping: Check for incorrect settings or external electrical noise.

- Failure to Trip: Verify the wiring and ensure the relay is within its operational parameters.

- Overheating: Ensure proper ventilation and check for obstructions around the relay.

Advantages of Using the Schneider LRE05

Energy Efficiency

The Schneider LRE05 helps in reducing energy consumption by ensuring motors run efficiently and are protected from damage.

Reliability

With robust construction and reliable performance, the LRE05 offers peace of mind to users, knowing their motors are well-protected.

Cost-effectiveness

By preventing motor damage and reducing downtime, the LRE05 contributes to overall cost savings in industrial and commercial operations.

Comparing the LRE05 with Other Models

Schneider LRE05 vs. LRE10

- Current Range: LRE05 offers a smaller range compared to the LRE10.

- Size: LRE05 is more compact, suitable for space-constrained applications.

- Cost: LRE05 is typically more affordable than the LRE10.

Schneider LRE05 vs. Competitors

- Quality: Schneider Electric’s reputation ensures high-quality components.

- Features: The LRE05 often offers more customizable settings and better integration options compared to competitors.

User Reviews and Feedback

Customer Testimonials

Many users appreciate the reliability and ease of installation of the Schneider LRE05. Here are some excerpts from satisfied customers:

- “The LRE05 has been a game-changer in our manufacturing setup, providing consistent motor protection.”

- “Installation was straightforward, and the relay has been performing flawlessly.”

Expert Opinions

Industry experts also commend the LRE05 for its robust design and performance, noting its suitability for various demanding applications.

Sustainability and Environmental Impact

Eco-friendly Features

The Schneider LRE05 is designed with sustainability in mind. It features energy-efficient components and is built to last, reducing the need for frequent replacements.

Contribution to Sustainable Practices

By ensuring motors run efficiently and preventing unnecessary energy consumption, the LRE05 supports sustainable industrial practices.

Conclusion

The Schneider LRE05 is a versatile and reliable overload relay, essential for protecting motors in both industrial and commercial applications. Its robust design, ease of installation, and customizable settings make it a valuable addition to any motor control system. With a focus on sustainability and cost-effectiveness, the LRE05 not only enhances operational efficiency but also contributes to environmental conservation.

FAQs

What is the lifespan of the Schneider LRE05? The Schneider LRE05 is designed for a long operational life, typically exceeding 10 years under normal conditions.

Can the LRE05 be used in extreme environments? Yes, the LRE05 is built to operate in a wide range of temperatures and high humidity environments, making it suitable for extreme conditions.

There are no reviews yet.