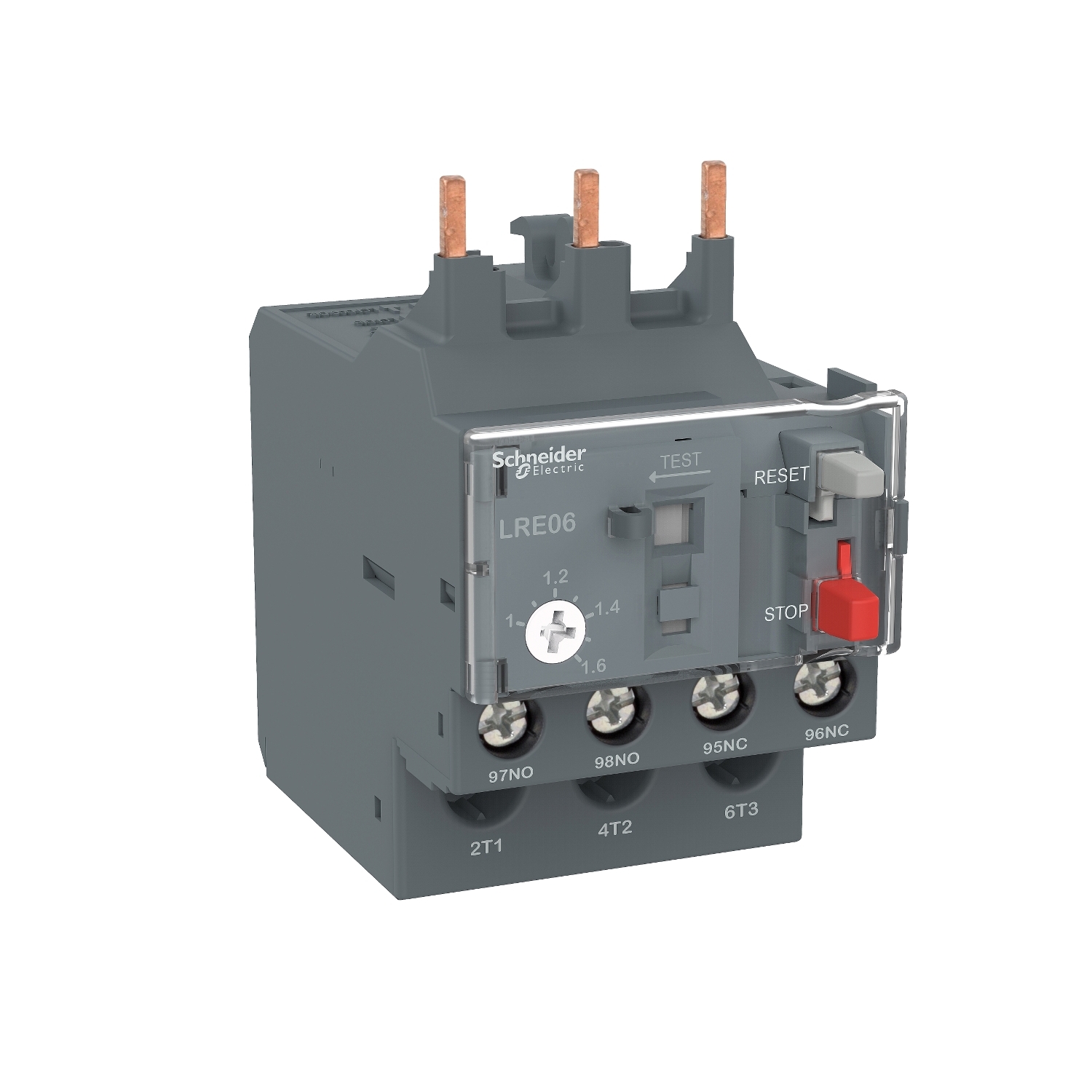

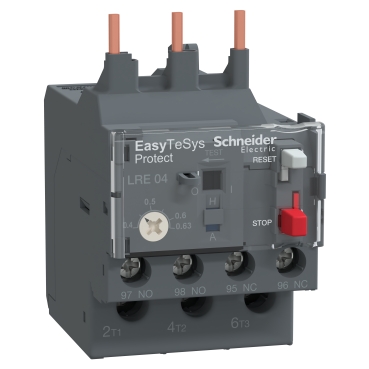

Schneider LRE32 | Thermal overload relay,EasyPact TVS,23…32A,for LRE01…E35,class 10A

1,372 EGP2,638 EGP (-48%)

Schneider LRE32| Thermal overload relay,EasyPact TVS,23…32A,for LRE01…E35,class 10A

Schneider LRE32 Description

Overview of Schneider Electric

History of Schneider Electric

Schneider Electric is a global leader in energy management and automation, with a history dating back to 1836. Over the years, they have evolved from a steel manufacturer to a key player in industrial automation, focusing on efficiency and sustainability.

Core Products and Services

Schneider Electric offers a broad range of products, from simple electrical components to complex automation systems. Their portfolio includes circuit breakers, sensors, switches, and programmable logic controllers (PLCs), all designed to enhance industrial operations.

Understanding the LRE32

General Features

The Schneider LRE32 is a thermal overload relay designed to protect electrical motors from overload and phase failure. It’s known for its robustness and reliability, ensuring that motors operate safely and efficiently.

Specifications and Technical Details

- Voltage: 690V

- Current Range: 0.1 to 32A

- Operating Temperature: -20°C to +60°C

- Mounting: DIN rail or screw mounting

Key Features of LRE32

Digital Display

One of the standout features of the LRE32 is its digital display, which provides real-time monitoring and easy-to-read diagnostics, simplifying the troubleshooting process.

Programmable Settings

The LRE32 offers programmable settings, allowing users to customize its operation according to specific needs. This flexibility makes it suitable for a wide range of applications.

Compact Design

Despite its powerful capabilities, the LRE32 boasts a compact design, making it easy to integrate into existing systems without requiring significant space.

Applications of Schneider LRE32

Industries Using LRE32

The LRE32 is widely used in various industries, including manufacturing, mining, and energy. Its reliability makes it a preferred choice for operations that demand consistent performance.

Typical Applications in Automation

In industrial automation, the LRE32 protects motors in conveyor systems, pumps, fans, and other critical machinery, ensuring minimal downtime and maximizing productivity.

Installation Process

Pre-Installation Requirements

Before installing the LRE32, ensure you have the necessary tools and that the environment meets the specified conditions, such as temperature and humidity levels.

Step-by-Step Installation Guide

- Turn off power: Ensure the power is completely off to avoid electrical hazards.

- Mount the relay: Install the LRE32 on a DIN rail or use screws for secure mounting.

- Connect wires: Follow the wiring diagram to connect the relay to the motor and control circuit.

- Configure settings: Use the digital display to set the desired parameters.

- Test the system: Turn on the power and test the relay to ensure it operates correctly.

Programming the LRE32

User Interface Overview

The user interface of the LRE32 is intuitive, featuring a digital display and a set of buttons for navigation and setting adjustments. The menu is straightforward, allowing quick access to various settings.

Common Programming Tasks

- Setting current range: Adjust the current settings based on the motor specifications.

- Configuring delay times: Set the appropriate delay times to prevent nuisance tripping.

- Testing the relay: Use the test function to simulate conditions and verify the relay’s response.

Benefits of Using Schneider LRE32

Enhanced Efficiency

The LRE32 improves motor efficiency by providing accurate protection and reducing unnecessary downtime, which can lead to significant cost savings in the long run.

Reliability and Durability

Designed for harsh industrial environments, the LRE32 is built to last, offering reliable performance and reducing the need for frequent replacements.

Comparing LRE32 with Competitors

Key Competitors

Key competitors of the LRE32 include Siemens SIRIUS 3RU and ABB TA25DU. These relays offer similar functionalities but differ in features and usability.

Comparative Analysis

While competitors may offer comparable protection, the LRE32 stands out with its user-friendly interface, compact design, and robust performance. Its ease of programming and reliability make it a preferred choice in many industries.

Troubleshooting Common Issues

Identifying Common Problems

- Overheating: Check for proper ventilation and ensure the current settings are correct.

- Nuisance tripping: Adjust the delay settings and verify the motor’s load conditions.

- Display errors: Reset the relay or update the firmware if necessary.

Solutions and Preventive Measures

Regular maintenance, including cleaning and inspecting connections, can prevent many common issues. Keeping the firmware up to date also ensures optimal performance.

Maintenance Tips

Routine Maintenance Practices

- Regular inspections: Check the relay and connections periodically for signs of wear or damage.

- Cleaning: Keep the relay and surrounding area free from dust and debris.

- Firmware updates: Ensure the relay’s firmware is current to benefit from the latest features and improvements.

Long-Term Care and Upkeep

Schedule annual check-ups and calibrations to maintain the relay’s accuracy and reliability. Replacing worn components timely can also extend the relay’s lifespan.

User Reviews and Feedback

Insights from Industry Professionals

Professionals appreciate the LRE32 for its reliability and ease of use. Many note that it significantly reduces downtime and maintenance costs.

Common Praises and Criticisms

While the LRE32 is praised for its robust design and user-friendly interface, some users wish for more advanced features like remote monitoring capabilities.

Future Developments

Upcoming Features and Improvements

Schneider Electric continuously innovates, and future versions of the LRE32 may include enhanced connectivity options, such as IoT integration for remote monitoring and control.

Trends in Industrial Automation

The trend towards smarter, more connected devices is likely to influence future iterations of the LRE32, making it an even more integral part of industrial automation systems.

FAQs About Schneider LRE32

What is the primary function of the Schneider LRE32?

The primary function of the Schneider LRE32 is to protect electric motors from overload and phase failure, ensuring safe and efficient operation.

How do I program the LRE32?

Programming the LRE32 involves using its digital display and buttons to set parameters such as current range and delay times, following the user manual for detailed instructions.

Can the LRE32 be used in harsh environments?

Yes, the LRE32 is designed to operate reliably in harsh industrial environments, with a wide operating temperature range and robust construction.

What industries commonly use the LRE32?

Industries such as manufacturing, mining, and energy commonly use the LRE32 due to its reliability and efficiency in protecting critical machinery.

How often should the LRE32 be maintained?

Routine maintenance should be performed regularly, with detailed inspections and calibrations at least once a year to ensure optimal performance.

Conclusion

The Schneider LRE32 is an essential component in industrial automation, providing reliable protection for electric motors. Its robust design, ease of use, and versatility make it a preferred choice across various industries. Whether you’re installing a new system or upgrading an existing one, the LRE32 offers the efficiency and reliability needed for modern industrial operations.

Additional information

| Weight | 0,13 kg |

|---|

Reviews

There are no reviews yet.