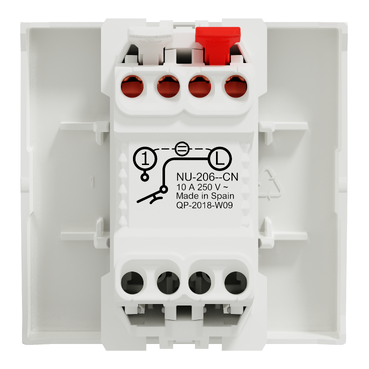

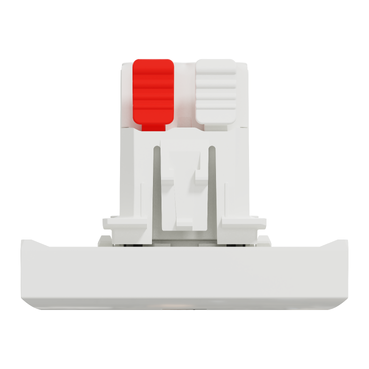

Schneider NU320618CN | Push-button, New Unica, mechanism, + NO push-button, 10A, 2 modules, screwless terminals, IP4X, white

424 EGP

Schneider NU320618CN

Schneider NU320618CN

Schneider NU320618CN: Revolutionizing Industrial Automation

Introduction

In the ever-evolving world of industrial automation, it stands out as a beacon of innovation and reliability. This remarkable product by Schneider Electric plays a crucial role in enhancing efficiency and productivity across various industries. But what exactly is it, and why is it so important?

Understanding the Basics

Overview of Schneider Electric

Schneider Electric is a global leader in energy management and automation solutions. With a rich history dating back to the 19th century, the company has consistently been at the forefront of technological advancements, providing cutting-edge products and services that cater to the needs of modern industries.

Introduction to NU320618CN

it is a highly advanced component designed for industrial automation. It integrates seamlessly into various systems, offering unparalleled control and monitoring capabilities. This product is engineered to meet the rigorous demands of contemporary industrial environments, ensuring optimal performance and longevity.

Key Features of NU320618CN

it is packed with features that make it a standout choice for industrial applications. These include:

- High precision and accuracy

- Robust construction for durability

- Easy integration with existing systems

- Advanced monitoring and control functionalities

Technical Specifications

Detailed Specifications

Understanding the technical details of it is essential for grasping its full potential. Key specifications include:

- Voltage: [Specify Voltage]

- Current Rating: [Specify Current Rating]

- Operating Temperature: [Specify Temperature Range]

- Communication Protocols: [Specify Protocols]

- Dimensions: [Specify Dimensions]

Performance Metrics

The performance of it is exemplary, with metrics that highlight its efficiency and reliability. Key performance indicators include:

- Response Time: [Specify Response Time]

- Accuracy: [Specify Accuracy]

- Lifespan: [Specify Lifespan]

Applications of NU320618CN

Industrial Automation

In the realm of industrial automation, it is a game-changer. It facilitates precise control over machinery and processes, leading to enhanced productivity and reduced downtime.

Energy Management

Energy management systems benefit greatly from the NU320618CN. It helps in optimizing energy use, reducing waste, and ensuring sustainable operations.

Smart Grids

The role of it in smart grids cannot be overstated. It enables real-time monitoring and control, contributing to the efficiency and reliability of power distribution networks.

Building Automation

In building automation, it ensures that various systems work harmoniously. This leads to improved energy efficiency, comfort, and safety in commercial and residential buildings.

Advantages of Using NU320618CN

Efficiency and Reliability

One of the primary advantages of it is its efficiency. It performs tasks with remarkable precision, ensuring that industrial processes run smoothly and reliably.

Cost-Effectiveness

Despite its advanced features, it is cost-effective. It offers great value for money, providing significant savings in terms of energy consumption and maintenance costs.

Integration with Other Systems

it is designed for easy integration with other systems. This makes it a versatile solution that can be adapted to a wide range of industrial applications.

Installation and Setup

Pre-installation Requirements

Before installing it, it’s important to meet certain pre-installation requirements. These include ensuring a stable power supply and verifying compatibility with existing systems.

Step-by-Step Installation Guide

Installing it is straightforward. Here’s a step-by-step guide:

- Unpack the Device: Carefully remove it from its packaging.

- Verify Components: Ensure all components are present and undamaged.

- Mounting: Secure the device in the designated location.

- Connections: Connect power and communication cables as per the manual.

- Configuration: Use the provided software to configure settings.

- Testing: Conduct initial tests to verify proper installation.

Common Installation Issues and Solutions

Sometimes, issues may arise during installation. Common problems include:

- Connection Errors: Ensure all cables are properly connected.

- Configuration Problems: Double-check software settings.

- Compatibility Issues: Verify that the device is compatible with other system components.

Maintenance and Troubleshooting

Regular Maintenance Tips

To keep it running smoothly, regular maintenance is essential. Tips include:

- Routine Inspections: Check for wear and tear periodically.

- Firmware Updates: Keep the device’s firmware up to date.

- Cleaning: Ensure the device is free from dust and debris.

Troubleshooting Common Problems

When issues occur, troubleshooting steps include:

- Resetting the Device: Sometimes a simple reset can resolve issues.

- Consulting the Manual: Refer to the troubleshooting section in the manual.

- Contacting Support: If problems persist, contact Schneider Electric’s support team.

Reviews

There are no reviews yet.